cnc and vmc machine details A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in . Learn how to wire an electric meter box with a detailed wiring diagram. Follow step-by-step instructions to ensure a safe and efficient installation.This video describes how you wire edge sheet metals for safety and durability.Sean Duke Bernadas BSECE 1-A TUPVBongo by KV https://youtube.com/c/KVmusicprod.

0 · vmc machine shop

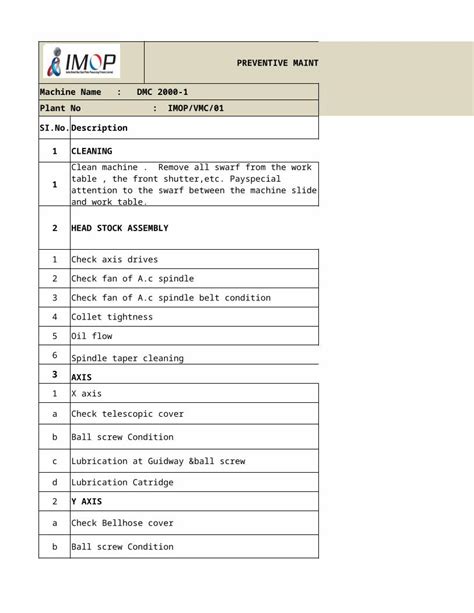

1 · vmc machine check list

2 · vmc machine basic knowledge

3 · vmc full form machine

4 · types of vmc machine

5 · haas vmc machine price

6 · difference between vmc and hmc

7 · cnc and vmc full form

click here to access the marble machine 3 documentation central - download files - submit contributions - access documentation -

A VMC machine, also known as a vertical machining center, is a type of CNC milling machine that utilizes vertical spindle orientation for cutting and shaping various materials. These machines offer numerous benefits, including .

VMC machines are typically equipped with a computer numerical control (CNC) system, which governs the machine’s movements and machining operations. The CNC system interprets machining instructions from a program, translates them .Understanding the distinctions between CNC and VMC machines is crucial for anyone involved in the manufacturing and machining industries. While both CNC and VMC technologies are . This article delves into the distinct features and applications of CNC (Computer Numerical Control), VMC (Vertical Machining Center), and HMC (Horizontal Machining Center) . A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in .

A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines .Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting .

vmc machine shop

The vertical mill’s computerized or electronic controls permit automation, selection/rotation of tools, repeatability, and contour control. These high-level(advanced) and present-day CNC machines have expanded the .CNC vertical machining center is a type of Computer Numerical Control VMC that has vertically oriented spindles that approach workpiece mounted on worktable from above and equipped with tool magazine system and automatic tool changer.In CNC vertical milling center, operators process the material on the table and the cylindrical cutters positioned vertically on a spindle axis. VMC machines are vertical cutting machines used to cut aluminum, steel, or other solid metals. .

A VMC machine, also known as a vertical machining center, is a type of CNC milling machine that utilizes vertical spindle orientation for cutting and shaping various materials. These machines offer numerous benefits, including increased precision, higher productivity, and reduced labor costs.VMC machines are typically equipped with a computer numerical control (CNC) system, which governs the machine’s movements and machining operations. The CNC system interprets machining instructions from a program, translates them into precise movements of the machine axes, and executes the desired machining tasks with accuracy and repeatability.Understanding the distinctions between CNC and VMC machines is crucial for anyone involved in the manufacturing and machining industries. While both CNC and VMC technologies are fundamental to modern precision machining, they serve different purposes and . This article delves into the distinct features and applications of CNC (Computer Numerical Control), VMC (Vertical Machining Center), and HMC (Horizontal Machining Center) machines, helping you understand which one is best suited for your needs.

A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in contemporary manufacturing for producing complex and intricate parts with .

A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines is that the spindle axis of a VMC is oriented vertically, rather than horizontally.Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting applications, CNC finds a special place. 3. In CNC, a manual intervention is required for changing the tool.The vertical mill’s computerized or electronic controls permit automation, selection/rotation of tools, repeatability, and contour control. These high-level(advanced) and present-day CNC machines have expanded the efficiency and productivity of the milling machines to the most significant level, bringing about the vertical milling center .CNC vertical machining center is a type of Computer Numerical Control VMC that has vertically oriented spindles that approach workpiece mounted on worktable from above and equipped with tool magazine system and automatic tool changer.

In CNC vertical milling center, operators process the material on the table and the cylindrical cutters positioned vertically on a spindle axis. VMC machines are vertical cutting machines used to cut aluminum, steel, or other solid metals. Using a VMC, you can reshape a hard piece of metal into any form that you require.A VMC machine, also known as a vertical machining center, is a type of CNC milling machine that utilizes vertical spindle orientation for cutting and shaping various materials. These machines offer numerous benefits, including increased precision, higher productivity, and reduced labor costs.

VMC machines are typically equipped with a computer numerical control (CNC) system, which governs the machine’s movements and machining operations. The CNC system interprets machining instructions from a program, translates them into precise movements of the machine axes, and executes the desired machining tasks with accuracy and repeatability.Understanding the distinctions between CNC and VMC machines is crucial for anyone involved in the manufacturing and machining industries. While both CNC and VMC technologies are fundamental to modern precision machining, they serve different purposes and . This article delves into the distinct features and applications of CNC (Computer Numerical Control), VMC (Vertical Machining Center), and HMC (Horizontal Machining Center) machines, helping you understand which one is best suited for your needs. A VMC (Vertical Machining Center) machine is a CNC machine with a vertically oriented spindle, used for precision milling, drilling, tapping, and boring. They are essential in contemporary manufacturing for producing complex and intricate parts with .

A VMC (Vertical Machining Center) is a type of CNC machine that is specifically designed for milling operations. The primary difference between a VMC and other types of milling machines is that the spindle axis of a VMC is oriented vertically, rather than horizontally.

Difference between CNC and VMC machines. 1. CNC machine can work in a maximum of 3 axes, whereas VMC machine can work in a maximum of 5 axes. 2. For milling operations, VMC is preferred than CNC. But for other cutting applications, CNC finds a special place. 3. In CNC, a manual intervention is required for changing the tool.The vertical mill’s computerized or electronic controls permit automation, selection/rotation of tools, repeatability, and contour control. These high-level(advanced) and present-day CNC machines have expanded the efficiency and productivity of the milling machines to the most significant level, bringing about the vertical milling center .

CNC vertical machining center is a type of Computer Numerical Control VMC that has vertically oriented spindles that approach workpiece mounted on worktable from above and equipped with tool magazine system and automatic tool changer.

vmc machine check list

In this article, we will see how to use a MIG welder to weld without gas. If you decide to use a regular MIG welder, you will have to replace the wire feed rollers inside the machine with a special type of rollers having groves in them.20 Pcs Nm Clamp Type Cable Connectors 1/4 Inch Metal Electrical Box Connectors Wire Clamps for Metallic Conduit Protect Cables Silver, Zinc Alloy

cnc and vmc machine details|haas vmc machine price